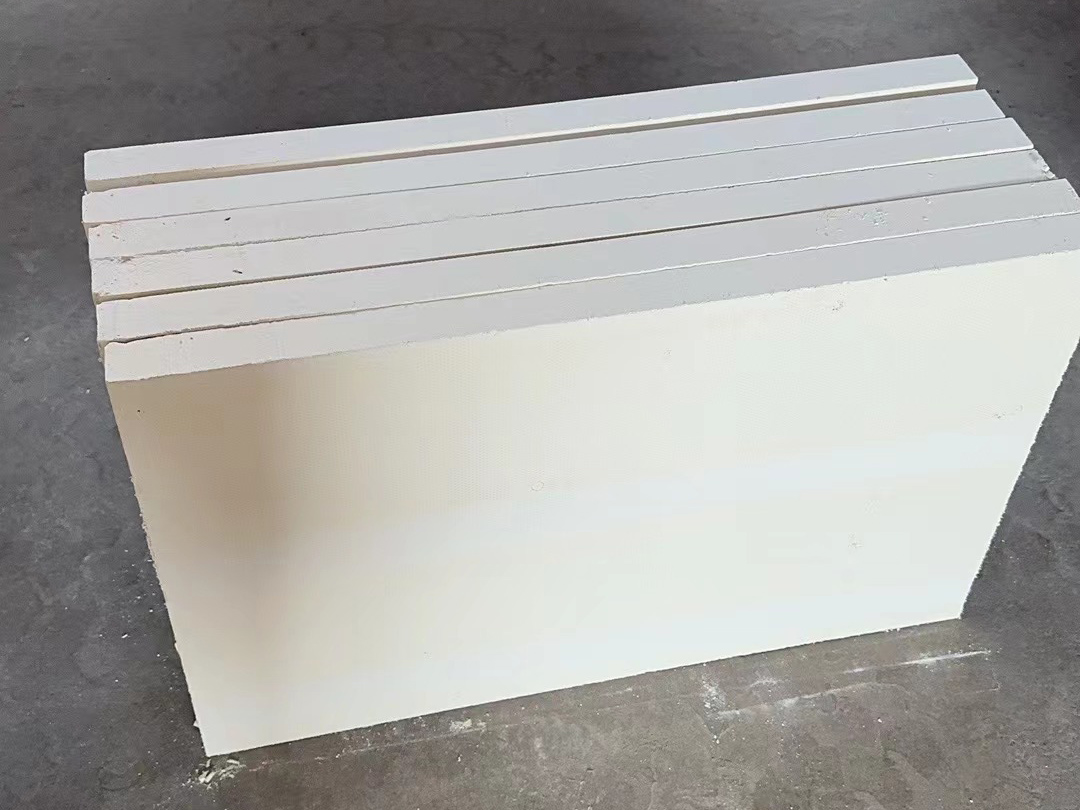

KRS 1260 degree resistance ceramic fiber Board energy-saving material

Product Introduction

Treatment: Ceramic fiber board is made of ceramic fibers and may cause itching and itching respiratory discomfort. Wear a mask and gloves when handling.

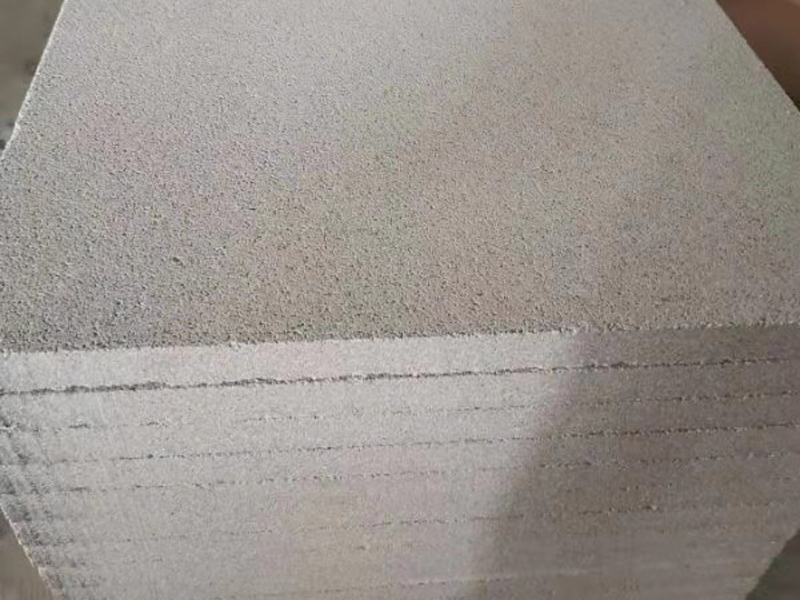

Cutting molding: Soft material. Can be cut with ordinary wheel saw and utility knife. If need a lot, die cutting is a good choice.

Bonding with adhesives: We have A14 high temperature adhesives made from high purity alumina and silicate raw materials.

It is designed to bond ceramic fiberboard together.

Use a vacuum cleaner to remove contaminants and dust to clean each surface to be glued.

Mix the adhesive well, as the material may settle when transported or placed.

Apply the adhesive to each surface to be bonded and touch the surfaces together.

Apply light but firm pressure for 1 minute to achieve initial setting, then gently turn Set the adhesive piece aside to ensure the bonding plane There is no force acting on it except the normal direction of the bonding plane.

Excess adhesive may seep out of the bonding site.

At room temperature or high temperature (not exceeding 100 ° C).

Dry for about 24 hours. The ceramic bond will be formed at temperatures above 1000° F.

product usage

Insulating support for brick and castable.

Furnace lining.

Industrial thermal processing equipment insulation.

High temperature gaskets and seals.

Flue and chimney linings in furnaces or kilns.

Molten metal tank cover.

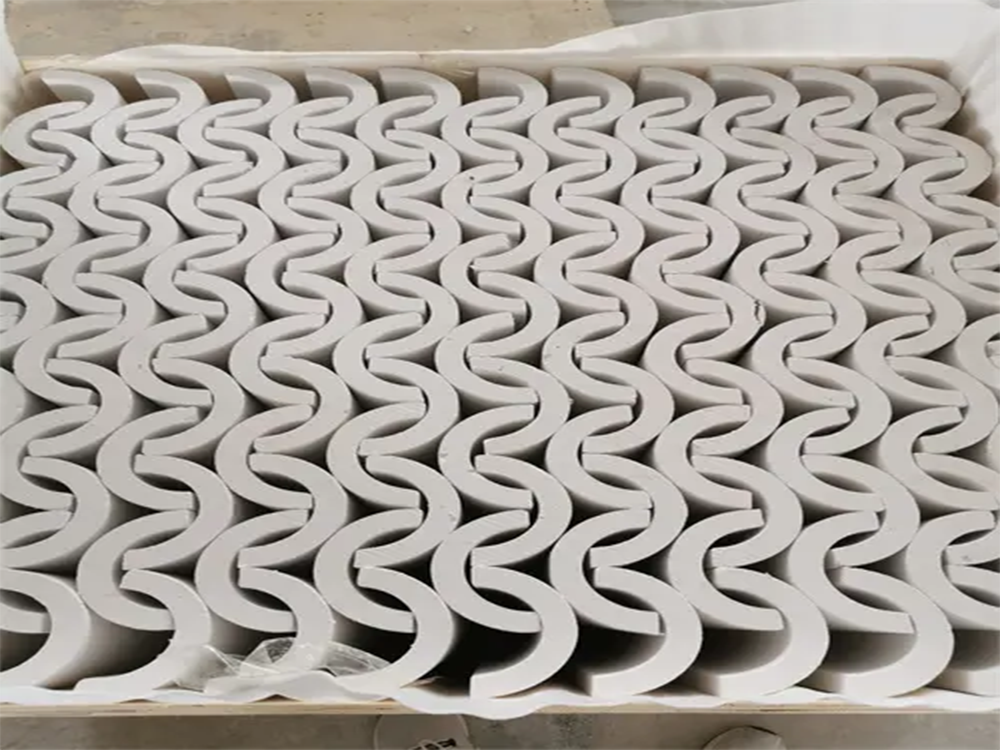

The expansion joint.

Industrial heat shields and thermal barriers.

Industrial combustion chamber construction.

Infrared element support.

Sheets covered with blankets are lined with hot faces.

Full thickness refractory lining.

High temperature boiler wall insulation.

Pouring form of castable.

Refractory lining for industrial furnace walls, tops, doors and chimneys.

Ideal for applications that experience vibration, mechanical stress and strong erosive forces.

Combustion chamber linings, boilers and heaters.

Backup insulation for brick and amorphous refractories.

Conveying molten aluminum and other non-ferrous metals.

Fire or heat resistance.

Suitable for hot surfaces in high speed or abrasive furnace atmospheres.

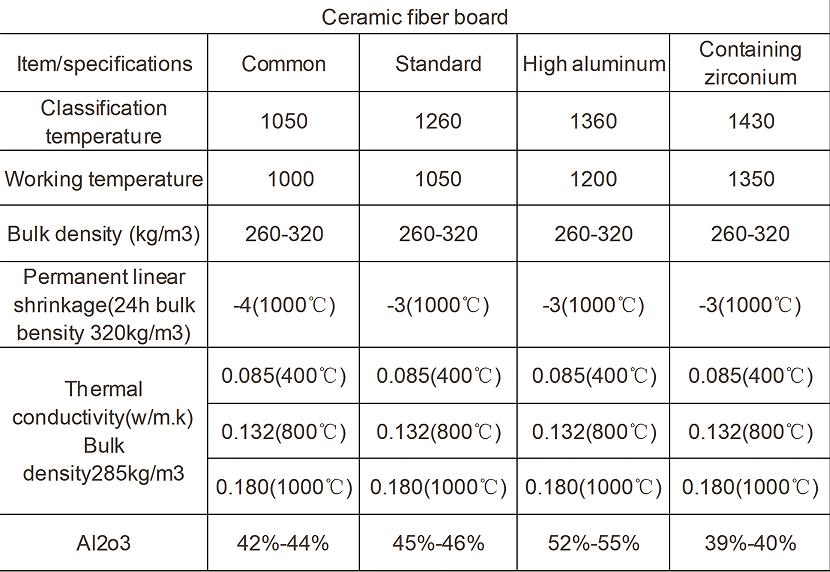

Product parameters

Packaging & Transportation

Product packaging

We can provide customers with carton packaging, wooden pallet packaging, carton + wooden pallet packaging, or wooden pallet winding packaging.

Carton packing: We can customize the carton shipping mark for customers.

Product transportation

Usually by sea, but also by air and land

Sample

As for our samples, in order to better cooperate with the customer, we can provide the samples for free, but the customer needs to pay the Courier fee.

description2