KRS Rock wool Pipe Fire and Soundproofing Insulation

Product Introduction

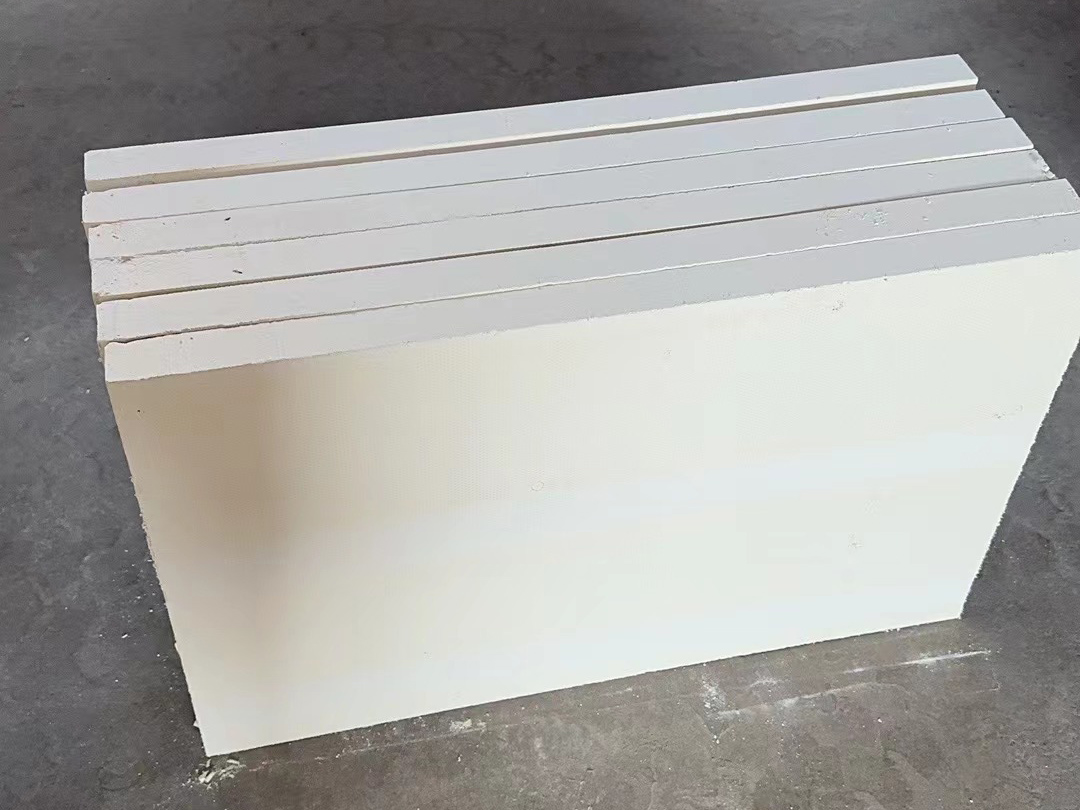

Rockwool pipe support blocks are made of high density mineral wool with high load capacity and are used to support pipes. It provides effective insulation to prevent thermal bridge and heat loss or entry into the ductwork through pipe supports.

The rockwool pipe support block is non-combustible and has a steam-controlled foil surface, making it a rugged product ideal for rough handling on site. Rockwool pipe supports are available in a variety of pipe sizes and insulation thicknesses and are combined with Qwikclamp pipe clips of corresponding sizes.

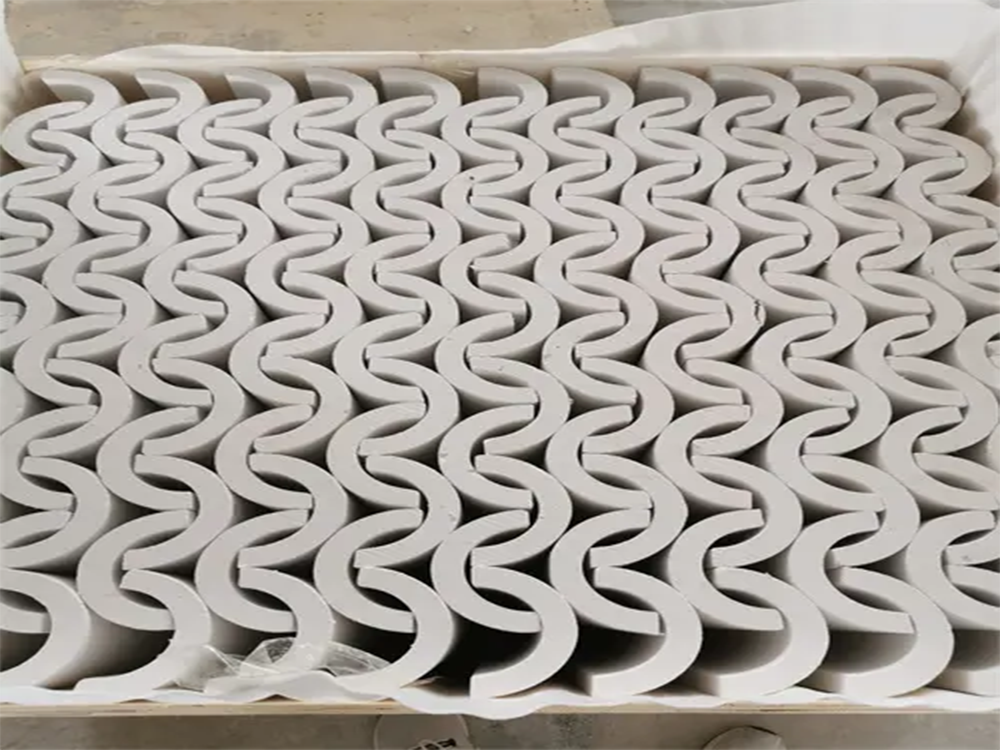

Rockwool material for pipe insulation and moisture resistance. It adopts the form of slit tube, easy to install, the mold structure is strong and durable, durable. Select the size corresponding to the nominal pipe size used and the preferred thickness of the jacket. Operating temperature up to 650oC.

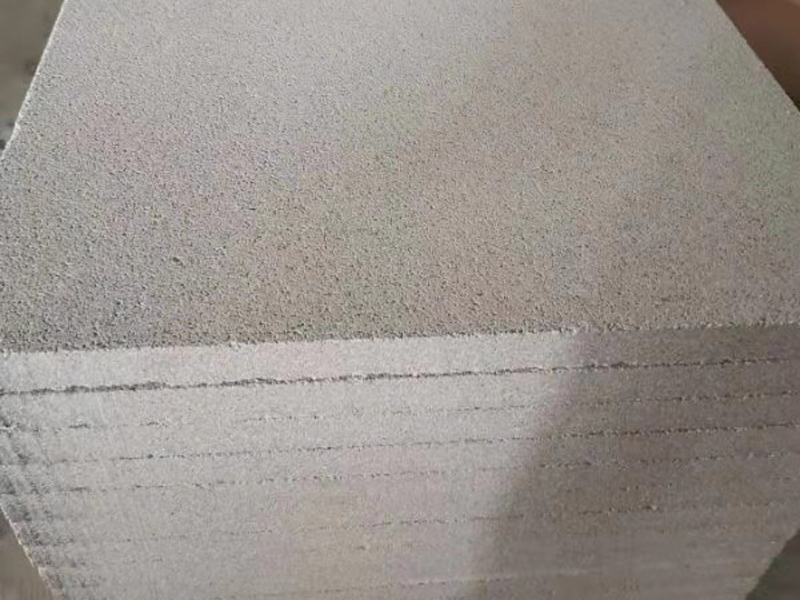

Rock wool is a versatile thermal insulation product used worldwide to provide efficient, cost-effective and environmentally friendly protection through its thermal, acoustic and fire protection properties. In addition, because the material can be made flexible, hard, dense or lightweight, resistant to compression, the physical properties can meet the requirements. It is made by spinning a molten mixture of natural rocks and recycled products into fine wool-like fibers that are bonded together using a thermosetting resin.

Since the eve of production in the 1930s, rockwool has a long history of application in many industries, and is gradually used in residential, commercial, Marine and industrial fields.

Today, it has become a standard in industrial plants worldwide as an important cost-effective insulation system component. In Australia, rockwool has been widely used in coal - and gas-fired power stations, petrochemical refineries, petrochemical plants, liquefied natural gas plants and fertilizer plants.

product usage

Rock wool has a wide range of uses in its different forms:

Industry: boilers, pipes, containers, storage tanks, pipes, chimneys, sound insulation materials. For energy saving, process control and personal protection.

Building: Passive fire protection, insulation, sound insulation, plumbing and ductwork.

Marine: Passive fire protection, A30, A60, H120 system, comfort insulation, floating floor.

Suitable for storage tank, heat exchanger, reactor, dust collector, chimney, oven, air conditioning piping system, refrigeration equipment and other plant and equipment process temperature control, energy saving and anti-condensation.

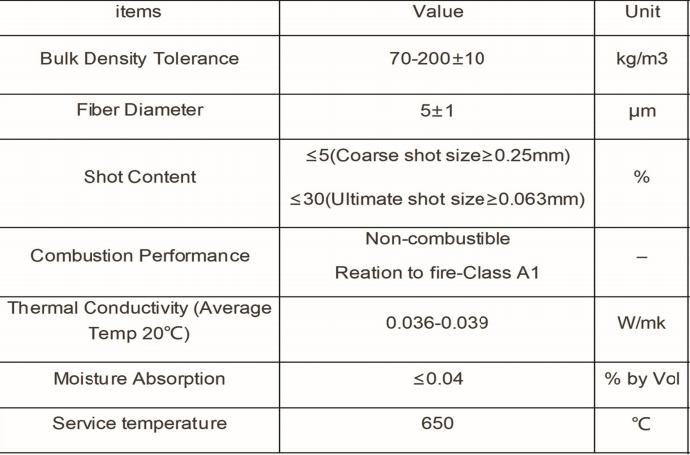

Product parameters

Packaging & Transportation

Product packaging

We provide plastic film packaging for our customers

We can provide OEM services for our customers

Product transportation

Usually by sea, but also by air and land

Sample

As for our samples, in order to better cooperate with the customer, we can provide the samples for free, but the customer needs to pay the Courier fee.

description2