What is the difference between 1.1000℃ high temperature calcium silicate insulation board and 650℃ asbestos-free calcium silicate products?

High temperature calcium silicate products are a kind of high efficiency and energy saving materials, at present, the application of the material in the field of high temperature has advantages, its excellent thermal insulation, thermal insulation performance has been generally recognized in the industry, it has been widely used in metallurgy, petroleum, light industry, building materials, machinery, electric power and other departments, as tower, tank, furnace, kiln wall insulation, thermal insulation materials. At present, China's mass production of calcium silicate products are tobermolite (5CaO·6SiO_2·5H_2O) as the main mineral composition of products, the highest use temperature of 650℃, called microporous calcium silicate products. Asbestos-free high temperature resistant calcium silicate products are based on hard calcium silicate (6CaO·6SiO_2·H_2O) as the main mineral composition of the products, the highest use temperature is 1050℃.

Calcium silicate insulation material is mainly composed of 5CaO·6SiO2·5H2O and 6CaO·6SiO2·5H2O, of which 5CaO·6SiO2·5H2O accounts for 30-45wt % of the total weight of calcium silicate insulation material, and the maximum use temperature of 5CaO·6SiO2·5H2O is 650℃; 6CaO·6SiO2·5H2O accounts for 55-70wt % of the total weight of calcium silicate insulation material, and the maximum use temperature of 6CaO·6SiO2·5H2O is 1000℃. The calcium silicate insulation material suitable for 650-800℃ is formed by evenly mixing the two substances. This kind of calcium silicate insulation material is prepared by the reaction process of dynamic method and static method, which fills the vacancy of calcium silicate insulation material between 650-800℃, and has unique advantages and good insulation effect. In the preparation process, the fineness of the raw material was optimized, the reaction rate was accelerated, and the product generation rate was increased.

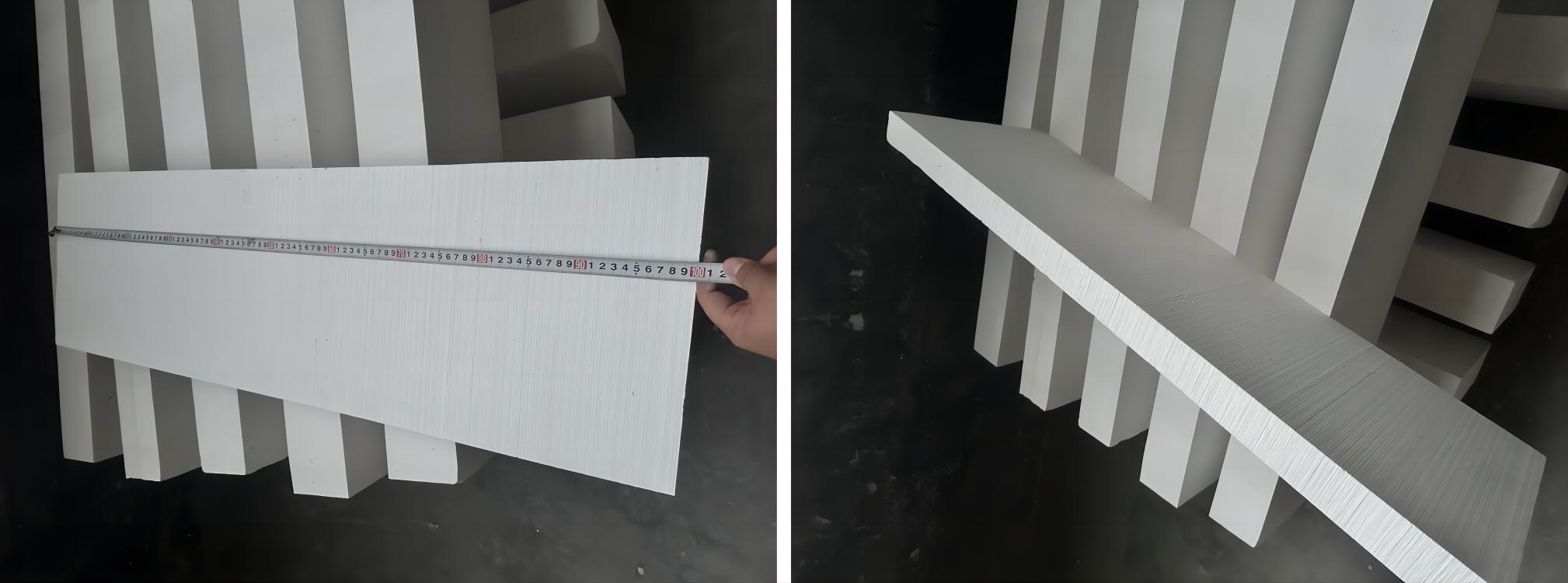

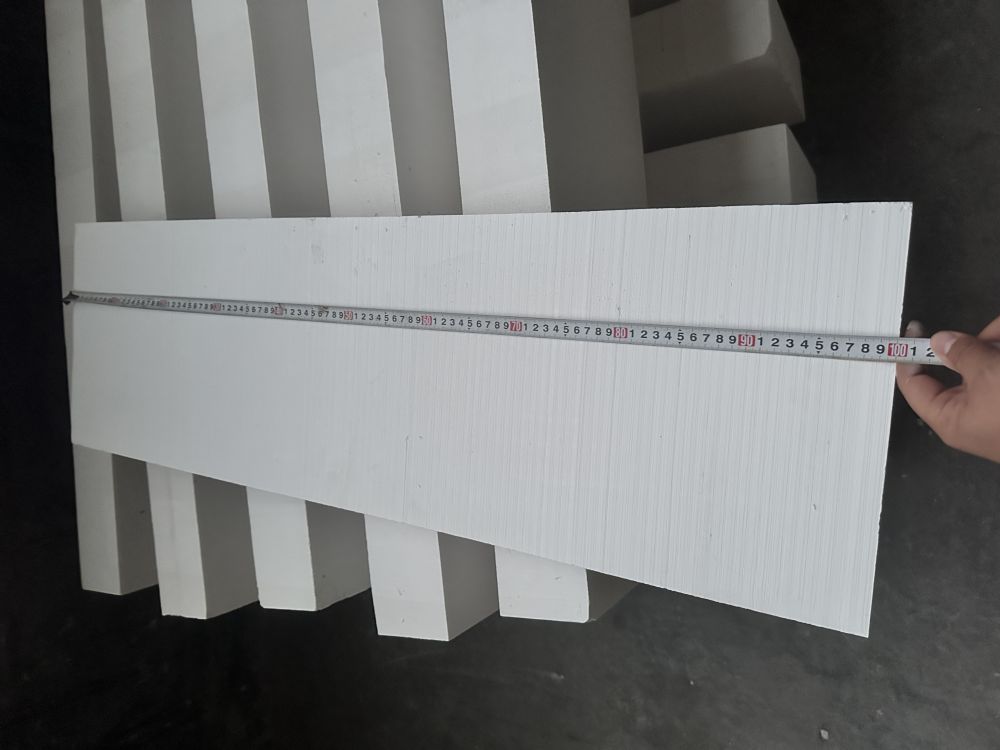

1000℃ high temperature calcium silicate insulation board is composed of hard calcium silicate carbohydrate and reinforced fiber, asbestos-free, high heat resistance temperature up to 1050℃, is an efficient energy-saving product. With high heat resistance temperature, strong heat insulation performance, low volume weight, high strength, good durability, corrosion resistance, cutting, sawing and other excellent construction characteristics, can be widely used in kiln energy saving and heat preservation projects.

Asbestos-free microporous calcium silicate board products (high temperature resistance 650℃) density: 230-250kg/m3, the main chemical structure is tobe mullite, with small thermal conductivity, high strength, high temperature, non-flammable, easy to process, no corrosion, pure and other characteristics, uses: Used in electric power, heat pipeline, chemical industry, metallurgical industry equipment, heat pipeline, boiler body, kiln body, etc. In recent years, it has been widely used in direct buried cylinder, plastic sleeve steel, composite insulation pipeline with glass fiber reinforced plastic as jacket, and can be processed into special-shaped products.